- Air Power Equipment

- Bristol Air Compressor

- Screw Air Compressor

- Oil Less Screw Air Compressor

- Oil Free Screw Air Compressor

- Oil Injected Screw Air Compressor

- Single Screw Air Compressor

- Double Screw Air Compressor

- Piston Air Compressor

- Oil Free Piston Air Compressor

- Hardware Using Piston Air Compressor

- Medium Pressure Piston Air Compressor

- Single Tank Piston Air Compressor

- Double Tank Piston Air Compressor

- Mining Piston Air Compressor

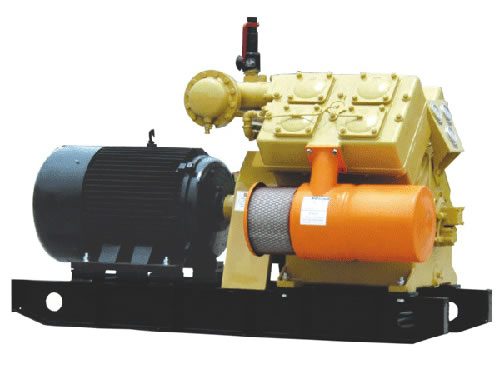

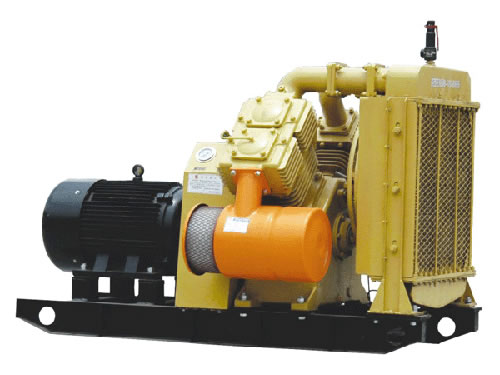

- Engineering Piston Air Compressor

- Portable Screw Air Compressor

- Other Air Compressors

- Drill Rig

- Drilling Machine

- Jack Hammer

- Alloy Cables

- Pyroelectric Infrared Sensor

- Compressed Air Drying Machine

- Generator Sets

- Construction Hoisting Machinery

- Crushing Plant

- Mucking Loader

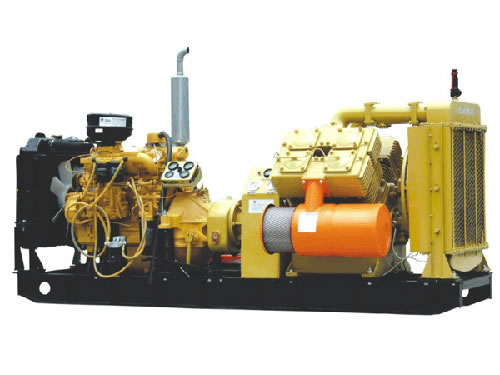

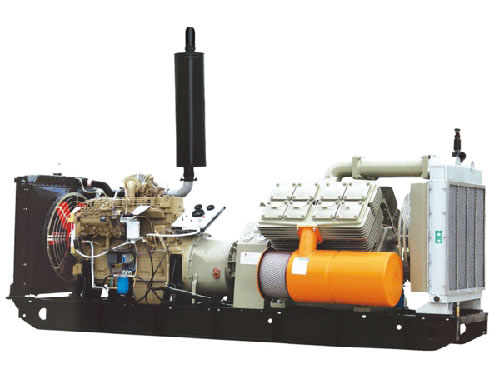

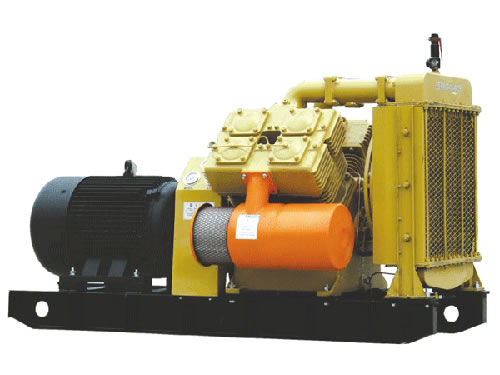

Engineering Piston Air Compressor

Description

Engineering piston air compressor is widely applied in various fields like engineering and mining field. Equipped with famous brand diesel, this piston compressor has the feature of strong power, low stoppage rate and reliable operation. Besides, this engineering piston air compressor possesses good cold-starting performance, making it adaptable to plateau and intense cold working conditions (For example, it can be applied in the Qinghai-Tibet railway construction site).

Characteristics

1. New Series, Replacing Products

Wind cooling and water cooling engineering piston air compressor series gathers the latest technological achievement of domestic and abroad piston compressor. The new design concept completely solve the problem of unreasonable match of air compressor of 3, 6, 9, 10 cubic meter and pneumatic machinery, high oil consumption and temperature, high rate of fault, which is a revolution of in engineering and mining air compressor.

2. Technology Gathering, Good Reliability

We use piston ring of automatic sealing technology to prolong lifetime of engineering piston air compressor with low consumption of lubricating oil. The optimized designed valve can effectively reduce the discharge resistance and temperature, enhance airflow volume and reduce power consumption of air compressor. Open inlet valve equipment and unloaded discharge technology can reduce energy consumption of air compressor. Compressed pressure of oil pump can be used to provide oil lubrication; and double oil route supply system can ensure reliable operation of engineering piston air compressor. Reasonable high heat abstraction wing plate, streamlined cooling fan and cooling pipe and water route can reduce air discharge temperature and energy consumption. Designed by computer, such piston compressor has better balance with small vibration, low noise and reliable operation.

3. Close to the Real Demand of Clients

By enlarging cylinder diameter and stroke, engineering piston air compressor can be provided with enough airflow and strong air discharge pressure, which can effectively enhance working efficiency of big and medium pneumatic rock hammer drill and DTH. This machine is equipped with diesel engine with automatic alarms upon high water temperature, low oil pressure of diesel engine and compressor. It also has automatic shutdown equipment of diesel engine, which has strong self-protection ability and high reliable operation to do the long distance wind supply work.

4. Diesel engine is from famous Yuchai with strong driving force, low accident rate and reliable function. It has the good function under low temperature to complete work on plateau and other cold environment. There are different diversities of engineering piston air compressors to meet demand of different clients with high cost-effectiveness, small investment and low cost.

LANTYPC Compressors is a specialized manufacturer of air compressors like engineering piston air compressors, screw compressor and piston compressors, etc. in China. Besides, we are engaged in oil injected screw air compressor, oil less screw type and oil free screw model, etc.

English

English Español

Español Русский

Русский